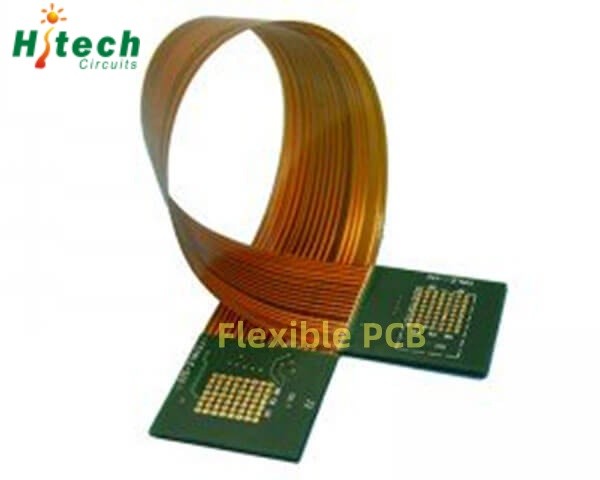

What is a flexible PCB board?

Flexible PCB circuit board, also called soft board, FPC board, is a kind of pcb, with excellent flexibility. FPC circuit board can complete the overall wiring work on one machine, which can be expanded and moved arbitrarily according to the space layout requirements, reduces the wiring volume, realizes the integration of component assembly and wire connection, and promotes electronic products to be smaller, lighter and thiner.

FPC flexible circuit board is made of polyester film or polyester imide, which is light and thin, high density, high flexibility, bendable and foldable, and has advantages that other types of circuit boards do not have. Compared with traditional interconnection technology, FPC flexible circuit boards can withstand millions of bending times, are easy to install, and have good heat dissipation, which are favored by the market.

https://hitechcircuits.com/pcb....-products/flexible-p