In the ever-evolving world of semiconductor manufacturing, optimizing resources and reducing waste are crucial objectives. The process of wafer reclaiming has emerged as a sustainable solution that not only helps in reducing costs but also minimizes the environmental impact associated with the production of new wafers. The concept of wafer reclaiming services in California (CA), sheds light on its benefits, the processes involved, and its role in promoting a sustainable semiconductor industry.

What are Wafer Reclaiming Services?

Wafer reclaiming services refer to the process of restoring used or rejected silicon wafers to a usable condition. These wafers might have undergone previous processing steps or been deemed unfit for their original intended purpose. Instead of discarding them, Wafer Reclaiming Services salvage and refurbish the wafers, thereby maximizing their value and reducing waste.

The Importance of Wafer Reclaiming:

The semiconductor industry heavily relies on silicon wafers, which serve as the foundation for manufacturing integrated circuits (ICs). However, the production of new wafers demands significant energy, raw materials, and financial resources. By opting for wafer reclaiming services, companies can decrease their reliance on new wafer production, leading to several benefits:

Cost Reduction: Wafer reclaiming services offer a cost-effective alternative to purchasing new wafers. Reclaimed wafers are often available at a fraction of the cost of new ones, enabling semiconductor manufacturers to optimize their budgets.

Resource Conservation: Reclaiming wafers helps conserve valuable resources such as silicon, chemicals, water, and energy. By reducing the consumption of these resources, wafer reclaiming contributes to a more sustainable and environmentally friendly semiconductor industry.

Reduced Waste Generation: The process of wafer reclaiming significantly reduces the amount of waste generated in the semiconductor manufacturing process. Instead of disposing of rejected or used wafers, companies can reclaim them, extending their lifespan and minimizing their environmental impact.

The Wafer Reclaiming Process:

· Initial Inspection and Sorting

The wafer reclaiming process begins with a thorough inspection of the used or rejected wafers. Each wafer undergoes a visual examination to identify defects, contamination, or other issues that might impact its reusability. Based on the inspection results, the wafers are sorted into different categories, such as reclaimable, partially reclaimable, or irreclaimable.

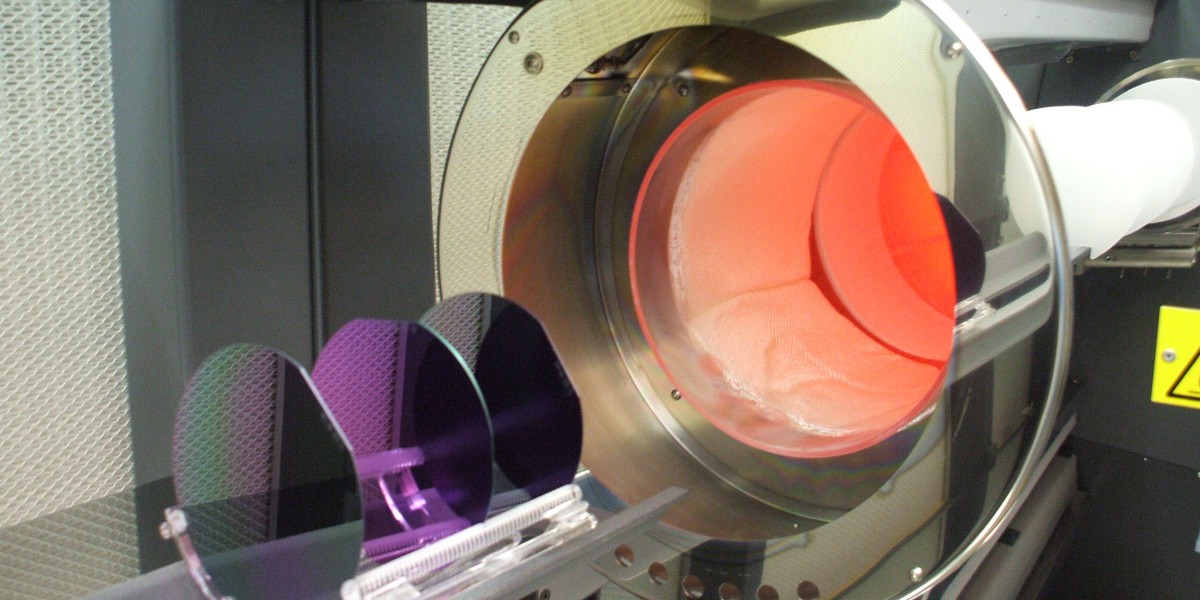

· Wafer Grinding and Polishing

In this stage, the wafers deemed reclaimable undergo grinding and polishing processes. The outer layers of the wafer, which may contain contaminants or defects, are removed through precision grinding. Subsequently, the wafers undergo a polishing process to smoothen the surface and remove any remaining imperfections.

· Cleaning and Etching

After grinding and polishing, the wafers go through a series of cleaning steps. This ensures the removal of any residual particles, chemicals, or contaminants from the wafer surface. The cleaning process is critical to achieving a high-quality reclaimed wafer that meets industry standards.

Following cleaning, the wafers may undergo an etching process, which involves selectively removing a thin layer of silicon. This step helps eliminate any remaining defects and contamination, further enhancing the quality of the reclaimed wafers.

· Metrology and Quality Control

To ensure the integrity and quality of the reclaimed wafers, metrology and quality control measures are implemented. These involve precise measurements and inspections to verify the dimensions, thickness, flatness, and other critical parameters of the wafers. Only wafers that meet the specified criteria proceed to the final stages of the wafer reclaiming process.

· Final Inspection and Packaging

In the final stage, the reclaimed wafers undergo a comprehensive inspection to validate their quality and performance. This includes various tests to assess electrical properties, crystallographic orientation, and surface cleanliness. Once the reclaimed wafers pass the inspection, they are carefully packaged to ensure protection during transportation and storage.

The Role of Wafer Reclaiming Services in Sustainability:

The adoption of wafer reclaiming services in California plays a significant role in promoting sustainability within the semiconductor industry. Here's how wafer reclaiming contributes to a more sustainable manufacturing ecosystem:

· Waste Reduction and Circular Economy

By reclaiming wafers, companies effectively reduce the amount of waste generated during semiconductor manufacturing. Reclaiming extends the lifespan of wafers that would otherwise be discarded, aligning with the principles of the circular economy. This waste reduction not only conserves valuable resources but also minimizes the need for new wafer production, resulting in a more sustainable supply chain.

· Energy and Resource Conservation

The production of new Silicon Wafers requires substantial energy consumption and the utilization of various resources. Wafer reclaiming services help conserve energy, raw materials, and chemicals by reusing existing wafers. By reducing the demand for new wafer production, the industry can minimize its environmental footprint and contribute to a greener future.

· Cost-Effective Solutions

In addition to their environmental benefits, wafer reclaiming services offer a cost-effective solution for semiconductor manufacturers. The reduced cost of reclaimed wafers allows companies to optimize their expenditure on materials and increase their competitiveness in the market.

Conclusion:

Wafer reclaiming services in California provide a sustainable and cost-effective solution for the semiconductor industry. By reclaiming and refurbishing used or rejected wafers, these services offer several advantages, including cost reduction, resource conservation, and waste reduction. Through the wafer reclaiming process, wafers undergo inspection, grinding, polishing, cleaning, and quality control stages, resulting in high-quality reclaimed wafers. Furthermore, wafer reclaiming contributes to sustainability by minimizing waste generation, conserving energy and resources, and promoting a circular economy. As the semiconductor industry continues to grow, embracing wafer reclaiming services becomes paramount to achieving a more sustainable and environmentally conscious future.