Market Overview

The foundry coke market refers to the global industry involved in the production and sale of foundry coke, a type of carbon material primarily used in the foundry industry. Foundry coke is a crucial component in the process of melting and casting metal in foundries, particularly in the production of iron and steel.

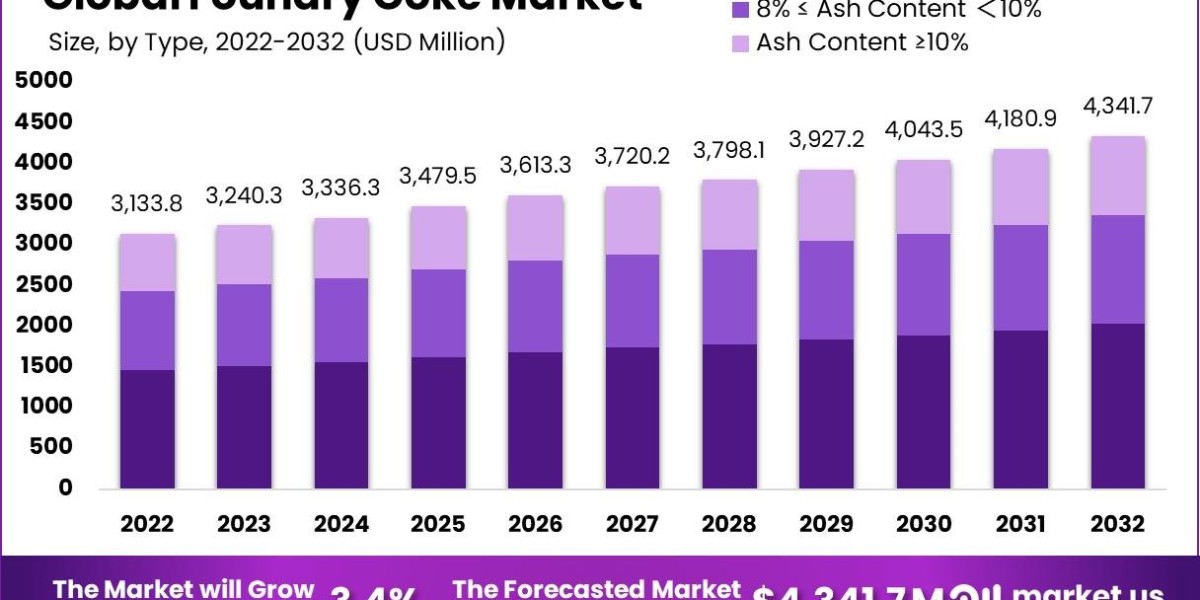

In 2022, the Foundry Coke Market was valued at USD 3,133.8 Million and is expected to reach USD 4,341.7 Million by 2032. Between 2023 and 2032, this market is estimated to register a CAGR of 3.4%.

Top Key Players

- ArcelorMittal

- Vedanta Resources Limited

- Drummond Company Inc.

- Nippon Coke & Engineering Company Limited

- Hickman Williams & Company

- Jiangsu Surun High Carbon Co. Ltd.

- Italiana Coke S.R.L.

- OKK Koksovny

- CARBO-KOKS

- Other Key Players

Request Free Sample Copy of this Report@: https://market.us/report/foundry-coke-market/request-sample/

Key Market Segmentation

Based on Type

- Ash Content <8%

- 8% ≤ Ash Content <10%

- Ash Content ≥10%

Based on Application

- Automotive Parts Casting

- Machinery Casting

- Material Treatment

Key Drivers

- Industrial Growth: The growth of industries, such as construction, automotive, and infrastructure, drives the demand for steel, directly impacting the demand for foundry coke.

- Urbanization: Increasing urbanization and infrastructure development in emerging economies fuel the demand for steel products, boosting foundry coke consumption.

- Technological Advancements: Innovations in coke production processes and technology enhance efficiency and reduce environmental impact, attracting more users.

- Environmental Regulations: Stricter environmental regulations encourage the adoption of cleaner coke production methods, driving innovation and market growth.

- Global Trade: International trade facilitates the movement of foundry coke to regions with high steel production, supporting market expansion.

Restraints

- Environmental Concerns: The carbon-intensive nature of coke production raises environmental concerns, leading to regulatory challenges and potential costs.

- Volatility in Raw Material Prices: Fluctuations in coal prices can impact the production cost of foundry coke, affecting profit margins.

- Competition from Alternatives: Growing competition from alternative materials like electric arc furnaces and scrap metal reduces the reliance on traditional foundry coke.

- Trade Barriers: Trade disputes, tariffs, and restrictions can disrupt the global supply chain for foundry coke.

- Technological Obsolescence: Outdated coke-making technologies hinder efficiency, sustainability, and cost-effectiveness.

Market Trends

- Green Coke Production: Growing emphasis on environmentally friendly coke production methods, such as biomass utilization and carbon capture technologies.

- Digitalization and Automation: Increasing adoption of digital technologies and automation to enhance efficiency, quality control, and data analysis in coke production.

- Circular Economy Initiatives: Integration of circular economy principles, including coke recycling and repurposing waste materials in the production process.

- Market Consolidation: A trend of market consolidation as larger companies seek to strengthen their global market presence and streamline operations.

- Supply Chain Optimization: Efforts to optimize the supply chain, reduce transportation costs, and ensure a stable supply of raw materials.

Recent Developments

- Environmental Compliance: Foundry coke producers are investing in technologies to reduce emissions and meet stringent environmental regulations, such as carbon capture and storage.

- Green Initiatives: Some companies are exploring the use of sustainable biomass as an alternative to coal in coke production, reducing the carbon footprint.

- Digital Transformation: Adoption of advanced analytics, IoT sensors, and automation in coke production for process optimization and quality control.

- Recycling Efforts: Initiatives to collect and recycle coke byproducts and waste materials, contributing to a more circular economy in the industry.

- Market Expansion: Companies are strategically expanding their market reach through partnerships, acquisitions, and investments in emerging economies with growing steel industries.

Conclusion

The foundry coke market is influenced by a complex interplay of drivers and restraints, with environmental concerns and competition from alternative materials posing challenges. However, the market is evolving through technological advancements, environmental compliance, and supply chain optimization. Recent developments indicate a growing commitment to sustainability, digitalization, and circular economy initiatives. The industry's ability to balance these factors, adapt to changing market dynamics, and innovate in response to environmental regulations will determine its long-term success and resilience in the global steel and iron production landscape.

Brows More Report

contact us

Global Business Development Team: Market.us

Market.us (Powered By Prudor Pvt. Ltd.)

Send Email:inquiry@market.us

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351, +91 78878 22626