Market Overview

Polyphenylene sulfide (PPS) fibers are high-performance synthetic fibers known for their excellent chemical resistance, thermal stability, and flame resistance. These characteristics make them ideal for various applications, including automotive, aerospace, electronics, industrial filtration, and more.

Here are some key points about the PPS fiber market:

- Properties and Applications:

- PPS fibers are resistant to most chemicals, acids, and bases, making them suitable for applications where exposure to harsh chemicals is a concern.

- They have a high melting point and excellent dimensional stability at elevated temperatures, making them ideal for high-temperature applications.

- PPS fibers are used in automotive components, industrial filtration, electrical insulation, and other applications where their unique combination of properties is valuable.

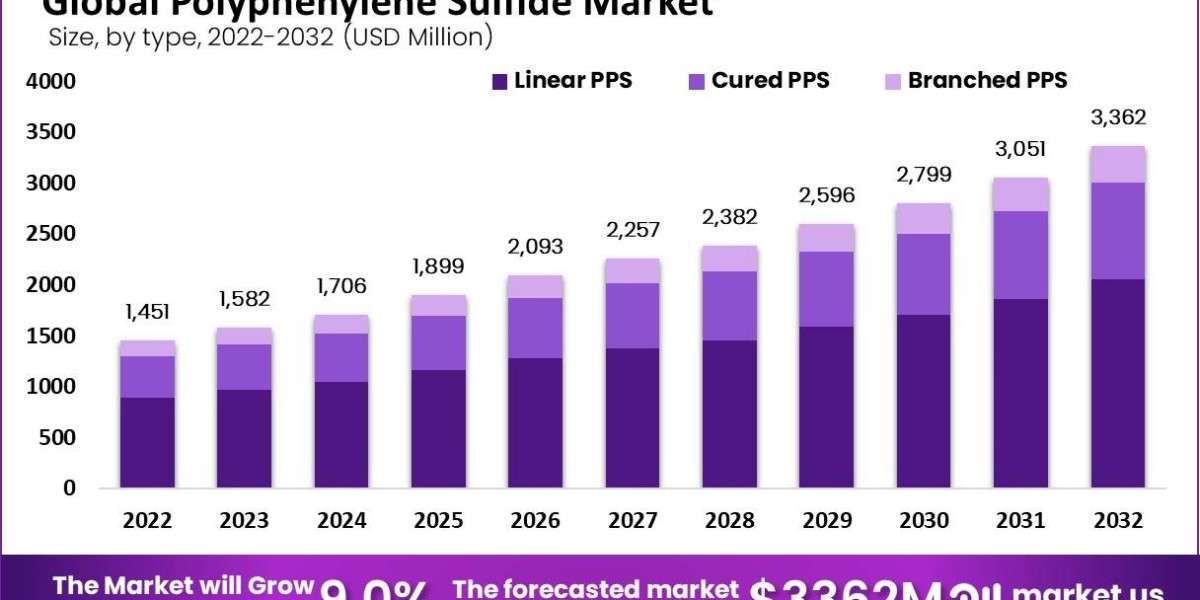

The global polyphenylene sulfide market size is expected to be worth around USD 3,362 million by 2032 from USD 1451 million in 2022, growing at a CAGR of 9.00% during the forecast period from 2022 to 2032.

Key Players

- Toray Industries Inc.

- DIC CORPORATION

- Solvay S.A.

- Lion Idemitsu Composites Co. Ltd

- Polyplastics Co. Ltd.

- Tosoh Corporation

- SK chemicals

- Chengdu Letian Plastics Co. Ltd.

- Celanese Corporation

- TEIJIN LIMITED

- SABIC

- Zhejiang NHU Co. Ltd.

- LG Chem

- RTP Company

- Ensinger

- Other Key Players

For more insights on the historical and Forecast market data from 2016 to 2032 – download a sample report @ https://market.us/report/global-polyphenylene-sulfide-fibre-market/request-sample/

Key Market Segments

Based on Type

- Linear PPS

- Cured PPS

- Branched PPS

Based on Application

- Automotive

- Electrical & Electronics

- Filter Bags

- Aerospace

- Industrial

- Coatings

- Other Applications

Demand

- Automotive Industry: PPS fibers are widely used in the automotive industry for various applications, including under-the-hood components, electrical connectors, and interior parts. The demand for PPS fibers in this sector is driven by the need for lightweight, durable, and chemically resistant materials to improve fuel efficiency and reduce emissions.

- Aerospace Industry: PPS fibers are also utilized in aerospace applications due to their high-temperature stability and resistance to chemicals. The aerospace industry's demand for PPS fibers is linked to the production of lightweight components and structures for aircraft and spacecraft.

- Electronics and Electrical: PPS fibers find use in electrical insulation and connectors in the electronics industry. The demand in this sector is driven by the need for reliable and thermally stable materials for electronic components and devices.

- Industrial Filtration: PPS fibers are employed in industrial filtration applications, such as filter bags for dust collection systems and liquid filtration. The demand in this segment is influenced by industrial growth and environmental regulations.

- Chemical Processing: PPS fibers are used in chemical processing equipment due to their chemical resistance. Demand in this sector depends on the expansion of the chemical industry and the replacement of traditional materials with PPS fibers.

Market Challenges

- Competition from Alternative Materials: PPS fibers compete with other high-performance materials such as carbon fiber, glass fiber, and thermoplastics like polyetheretherketone (PEEK). Competing materials may offer similar or even better properties for certain applications, making it essential for PPS fiber manufacturers to demonstrate their advantages effectively.

- Price Sensitivity: While PPS fibers offer outstanding properties, they can be more expensive than some other synthetic fibers, limiting their adoption in price-sensitive markets. Cost-effective manufacturing methods and economies of scale are necessary to address this challenge.

- Market Fragmentation: The PPS fiber market is relatively small compared to larger synthetic fiber markets. Market fragmentation can make it challenging for manufacturers to achieve economies of scale and reduce production costs.

- Raw Material Costs: The cost of raw materials used in PPS fiber production can fluctuate, affecting the overall cost structure of PPS fibers. Manufacturers need to manage these fluctuations to maintain competitive pricing.

- Environmental Concerns: Like other synthetic materials, the production and disposal of PPS fibers can have environmental implications. Increasing environmental regulations and consumer preferences for sustainable materials can pose challenges to the market.

Market Opportunities

- Automotive Lightweighting: As automotive manufacturers continue to seek ways to reduce vehicle weight to improve fuel efficiency and reduce emissions, PPS fibers can play a crucial role. The demand for lightweight materials in automotive components, such as engine components and interior parts, presents a significant growth opportunity for PPS fiber manufacturers.

- Aerospace Applications: The aerospace industry requires materials that can withstand high temperatures and harsh environments. PPS fibers can find increased use in aircraft components, satellite systems, and spacecraft, particularly in applications requiring high-temperature resistance and lightweight properties.

- Electronics and Electrical: PPS fibers are valued for their electrical insulation properties and chemical resistance. As electronic devices become smaller and more complex, PPS fibers can be used in various electrical components and connectors.

- Industrial Filtration: There is a growing emphasis on industrial air and liquid filtration due to environmental regulations and the need to maintain clean industrial processes. PPS fibers can be employed in filter media for applications such as air pollution control and water treatment.

- Sustainability and Environmental Regulations: PPS fibers are known for their chemical resistance and durability, making them suitable for long-lasting and sustainable applications. Companies can market PPS fibers as eco-friendly alternatives to materials that require frequent replacement.

Key Benefits

- Chemical Resistance: PPS fibers are highly resistant to a wide range of chemicals, including acids, bases, and organic solvents. This property makes them suitable for applications where exposure to corrosive substances is a concern, such as in chemical processing equipment and industrial filtration.

- Thermal Stability: PPS fibers have a high melting point and excellent thermal stability. They can withstand elevated temperatures without significant degradation, making them ideal for high-temperature applications in automotive, aerospace, and electronics.

- Flame Resistance: PPS fibers are inherently flame-resistant and exhibit self-extinguishing properties. They do not readily support combustion and are often used in applications where fire safety is critical, such as electrical insulation.

- Dimensional Stability: PPS fibers maintain their shape and dimensional stability even at high temperatures. This property is valuable in applications that require precise tolerances and resistance to thermal expansion.

- Low Moisture Absorption: PPS fibers have low moisture absorption properties, which means they do not absorb moisture easily. This makes them suitable for applications where moisture resistance is essential.

Top 5 Trends

- Sustainability and Environmental Concerns:

- Sustainability remained a prominent trend, with a growing emphasis on environmentally friendly materials and manufacturing processes.

- Materials that offered improved recyclability and reduced environmental impact gained traction.

- Regulations and consumer demand for eco-friendly products drove companies to innovate and adopt sustainable practices.

- Lightweighting for Automotive and Aerospace:

- Lightweight materials continued to be a priority in the automotive and aerospace industries to improve fuel efficiency, reduce emissions, and enhance performance.

- Materials like PPS fibers found increased use in these sectors due to their lightweight and high-performance properties.

- Advanced Composite Materials:

- The use of advanced composite materials, including PPS-based composites, was on the rise in various industries.

- Composites offered a balance of strength, weight reduction, and durability, making them appealing for applications in automotive, aerospace, and more.

- Digitalization and Industry 4.0:

- The adoption of digital technologies, such as artificial intelligence (AI), the Internet of Things (IoT), and data analytics, was transforming manufacturing processes.

- Smart manufacturing and real-time data analysis allowed for more efficient production and better quality control.

- Customization and Additive Manufacturing:

- Customization and rapid prototyping gained importance in manufacturing.

- Additive manufacturing (3D printing) continued to advance, enabling the creation of complex, customized components with materials like PPS.

Conclusion

In conclusion, polyphenylene sulfide (PPS) fibers offer a range of unique properties and benefits, including chemical resistance, thermal stability, flame resistance, and more. These properties make PPS fibers valuable in various industries, including automotive, aerospace, electronics, industrial filtration, and beyond.

While the PPS fiber market faces challenges such as competition from alternative materials and price sensitivity, it also presents numerous opportunities for growth and innovation. These opportunities include addressing sustainability concerns, meeting the demand for lightweight materials, expanding into new applications, and leveraging technological advancements.

The materials industry, including PPS fibers, is influenced by broader trends such as sustainability, lightweighting, advanced composites, digitalization, and customization. Staying informed about these trends and adapting to evolving market dynamics is essential for companies operating in the PPS fiber market.

contact us

Global Business Development Team: Market.us

Market.us (Powered By Prudor Pvt. Ltd.)

Send Email:inquiry@market.us

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351, +91 78878 22626

Website:https://market.us/