Positive Displacement Pumps Market Introduction

The global positive displacement pumps market size was almost USD 13.87 billion in 2023. The market is expected to grow at a CAGR of 4.8% over the forecast period of 2024-2032. The industry is further expected to attain a value of around USD 21.15 billion by 2032. These statistics reflect the growing importance of positive displacement pumps in various industries. In this blog post, we will explore the advantages of using positive displacement pumps in industrial processes.

I. Understanding Positive Displacement Pumps

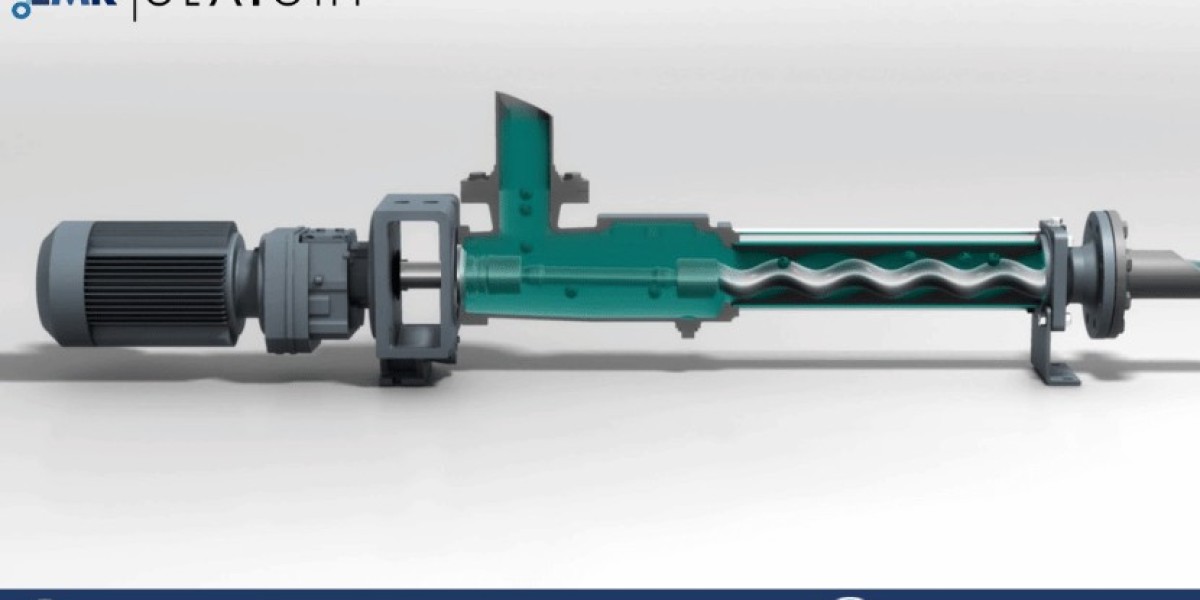

Before delving into their advantages, it's essential to understand what positive displacement pumps are and how they work. Positive displacement pumps are a category of pumps that move fluid by trapping a fixed amount of it and then forcing it into the discharge pipe. They differ significantly from centrifugal pumps, which operate on a different principle.

Positive displacement pumps are further categorized into various types, including rotary lobe pumps, gear pumps, piston pumps, and diaphragm pumps. Each type has unique characteristics and is suitable for specific applications.

II. Advantages of Positive Displacement Pumps

Precise Flow Control

One of the primary advantages of positive displacement pumps is their ability to provide precise flow control. They maintain a consistent flow rate regardless of variations in pressure or viscosity. This makes them ideal for applications where accuracy is crucial, such as in the pharmaceutical and chemical industries.

Positive displacement pumps excel at handling viscous fluids with ease. Unlike centrifugal pumps, which struggle with thick or sticky substances, positive displacement pumps maintain their efficiency even when dealing with materials like syrups, adhesives, or heavy oils. This characteristic ensures a steady and reliable flow.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/positive-displacement-pumps-market/requestsample

Handling Variable Viscosity

Another significant advantage is their ability to handle fluids with variable viscosity. While many pumps struggle with changes in fluid consistency, positive displacement pumps adapt seamlessly. They are equally effective with both thick and thin fluids, making them versatile for a wide range of applications.

Self-Priming Capabilities

Positive displacement pumps are often self-priming, which means they can draw fluid into the pump without external assistance. This is particularly valuable in situations where the pump needs to lift fluid from a lower level or when dealing with air or gas pockets. Their self-priming capabilities simplify the setup and operation of these pumps.

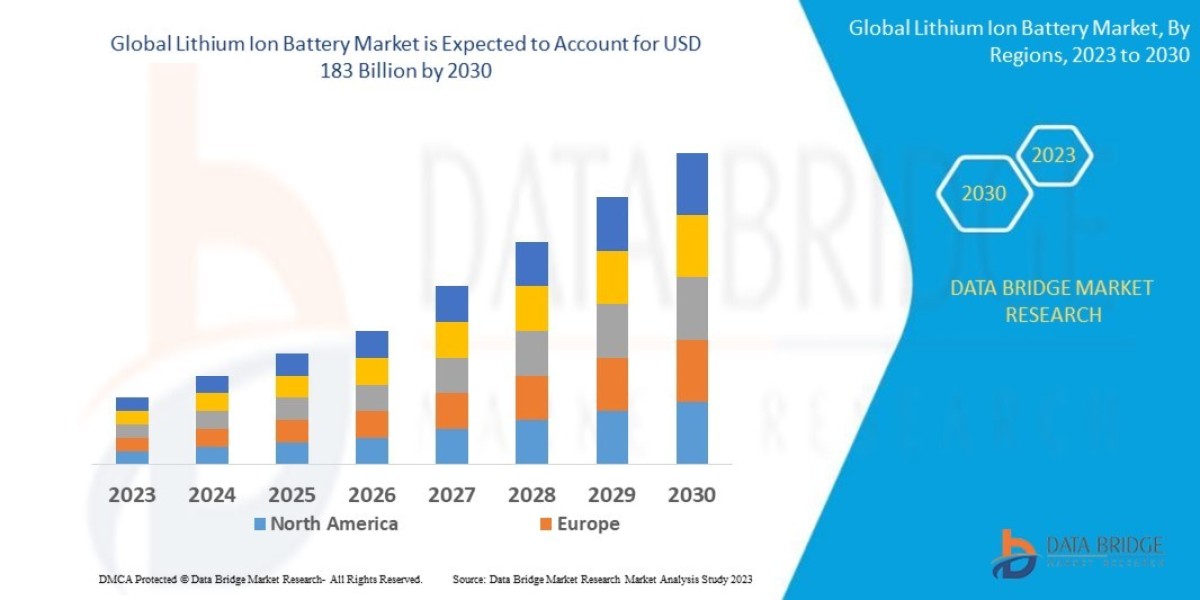

High Efficiency and Energy Savings

Efficiency is a critical factor in any industrial process. Positive displacement pumps are known for their high efficiency, which translates to energy savings. They work at a consistent level of performance, reducing the need for excessive power consumption. This not only lowers operational costs but also contributes to a more sustainable and eco-friendly operation.

Suitable for High-Pressure Applications

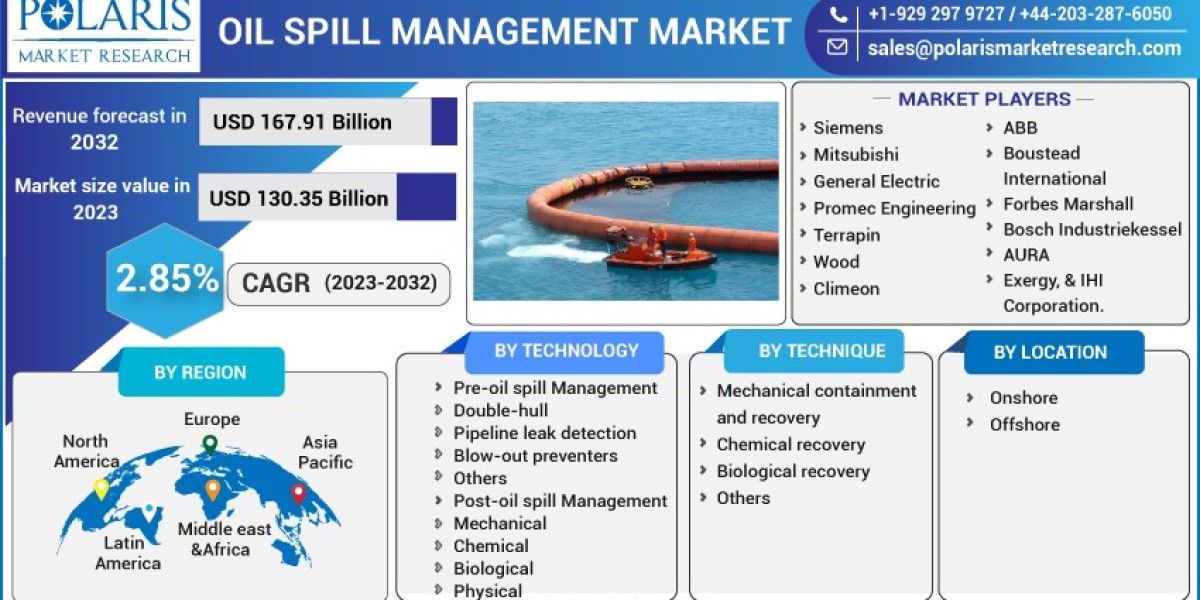

Positive displacement pumps are well-suited for high-pressure applications. They can generate the necessary force to move fluids against significant resistance, making them indispensable in processes where pressure is a critical factor. Industries such as oil and gas, mining, and power generation rely on positive displacement pumps to handle high-pressure tasks effectively.

Minimal Shear and Pulsation

In certain applications, shear and pulsation can be detrimental to the quality of the product being pumped. Positive displacement pumps minimize shear forces, ensuring that delicate or sensitive materials are handled gently. This is especially important in industries like food and beverage, where product integrity is paramount.

Versatility in Handling Abrasive and Sensitive Materials

Positive displacement pumps exhibit versatility when it comes to handling materials. They can transport abrasive substances without excessive wear and tear on the pump components. Additionally, they are suitable for pumping sensitive or fragile materials without causing damage, making them essential in industries such as mining, construction, and cosmetics.

III. Real-World Applications

To better understand the advantages of positive displacement pumps, let's explore some real-world applications in various industries:

A. Positive Displacement Pumps in Chemical Processing

In the chemical industry, precision and reliability are critical. Positive displacement pumps are widely used to handle corrosive and viscous chemicals, ensuring accurate dosing and preventing leaks or spills. Their ability to maintain a consistent flow rate is crucial for maintaining the quality of chemical products.

B. Use Cases in Food and Beverage Industry

Food and beverage processing require pumps that can handle a wide range of products, from thick sauces to delicate creams. Positive displacement pumps play a vital role in ensuring the efficient transfer of ingredients and maintaining product consistency. They are commonly used for tasks like transferring chocolate, syrup, and dairy products.

C. Pharmaceutical and Biotech Manufacturing

In pharmaceutical and biotech manufacturing, precision and sterility are paramount. Positive displacement pumps are employed for the precise dosing of pharmaceutical ingredients, ensuring the quality and safety of medical products. Their ability to handle sensitive materials without contamination is crucial in this industry.

D. Oil and Gas Sector

The oil and gas industry demands pumps that can handle high-pressure and high-viscosity fluids. Positive displacement pumps are employed in drilling operations, crude oil transfer, and refining processes. Their reliability and efficiency make them a preferred choice in this demanding sector.

E. Water Treatment and Wastewater Management

Positive displacement pumps are used in water treatment and wastewater management to move various types of fluids, including sludge and chemicals. Their versatility in handling different materials, coupled with their precise flow control, ensures the effectiveness of these processes.

IV. Maintenance and Best Practices

To maximize the advantages of positive displacement pumps, proper maintenance and adherence to best practices are essential. Here are some tips:

A. Routine Maintenance Tips

- Regularly inspect and lubricate pump components.

- Check for wear and tear on seals, gaskets, and valves.

- Monitor fluid levels and temperatures.

- Keep the pump and surrounding area clean to prevent contamination.

- Follow manufacturer-recommended maintenance schedules.

B. Troubleshooting Common Issues

- Address leaks promptly to prevent environmental hazards.

- Investigate unusual noises or vibrations and address them immediately.

- Monitor pump performance for deviations from the expected flow rate.

- Ensure proper alignment of pump components.

C. Importance of Proper Lubrication and Sealing

- Use the correct lubricants to extend the life of pump components.

- Ensure proper sealing to prevent leaks and maintain efficiency.

- Regularly inspect and replace seals and gaskets as needed.

Media Contact:

Company Name: Claight Corporation

Contact Person: Louis Wane, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com